Product Description

Glass processing chiller is one of the models of chillers, which cools normal temperature water to a certain temperature through the compressor of the chiller to enhance the cooling of molds or machines. It is used as a standalone unit, with a built-in fan as the heat dissipation device. There are mainly three interconnected systems: refrigerant circulation system, water circulation system, and electrical self-control system.

Refrigerant circulation system:

The liquid refrigerant in the evaporator of a glass processing chiller absorbs heat from water and begins to evaporate. Eventually, a certain temperature difference is formed between the refrigerant and water, and the liquid refrigerant completely evaporates into a gaseous state. It is then sucked in and compressed by a compressor (increasing pressure and temperature). The gaseous refrigerant releases heat through a condenser and condenses into a liquid. After being throttled by an expansion valve (or capillary tube), it becomes a low-temperature and low-pressure refrigerant that enters the evaporator, completing the refrigerant circulation process.

Water circulation system:

The water pump is responsible for extracting water from the water tank and pumping it to the equipment that the user needs to cool. The chilled water takes away the heat and rises in temperature before returning to the chilled water tank.

Electrical self-control system:

Including power supply and automatic control parts.

The power supply is supplied to compressors, fans, water pumps, etc. through contactors.

The automatic control part includes a temperature controller, pressure protection, delay device, relay, overload protection, etc., which are combined to achieve functions such as automatic start stop and protection based on water temperature.

Features of air-cooled chiller unit:

Air cooled chillers can be used in small systems, while the vast majority of large units are water-cooled. The initial investment for water-cooled engines is slightly less than that for air-cooled engines But with the addition of cooling towers and electronic water treatment equipment in the computer room, there are not many places to go! Moreover, in terms of long-term operation, the refrigeration efficiency of water-cooled units will relatively decrease, while air-cooled units will not.

The air-cooled chiller unit adopts air cooling method, which eliminates the essential cooling tower, cooling water pump and pipeline system of the cooling water system, avoids condenser scaling and water pipe blockage in areas with poor water quality, and also saves water resources. It is currently the most economical and simple model for maintenance and repair of cold water air conditioning equipment products.

The one-time investment for glass processing chillers is slightly higher than that for water-cooled chillers, but the annual operating cost is lower than that of water-cooled chillers. The building cost of the computer room is the lowest among various air conditioning cold and heat source systems, and the maintenance cost is about half of that of water-cooled or boiler systems.

The noise and volume of glass processing chillers are higher than those of water-cooled ones, so they can only be installed outdoors. Most water-cooled units are installed indoors.

Features of glass processing cold water machine:

1. Compressor high and low pressure protection, internal overheating protection

2. Low water level alarm device, low water temperature anti icing alarm

3. Adopting imported compressors from Europe, America, and Japan

4. The welding interface of the refrigeration system adopts oxygen free welding method to reduce oxides and achieve a smooth surface

5. The throttling components are made by Danfoss from Denmark and Eco from the United States

6. The water tank is made of SUS304 stainless steel to prevent corrosion and water leakage

7. RS485 communication function for automated management (optional)

8. Adopting stainless steel sheet metal, coil, shell and tube, and finned high-efficiency heat exchangers

9. Electrical devices supplied from OMRON,FUJI LG,MOELLER,SEHEIDER

10. Control method: Imported microcomputer or PLC control (optional)

11. Complete safety assurance, no need for professional personnel for fault prompts, repairs, and maintenance

12. Can save more than 30% of energy

13. SJ-10AD and above use two sets of compressors, which can be used separately or together

Glass processing chiller is one of the models of chillers, which cools normal temperature water to a certain temperature through the compressor of the chiller to enhance the cooling of molds or machines. It is used as a standalone unit, with a built-in fan as the heat dissipation device. There are mainly three interconnected systems: refrigerant circulation system, water circulation system, and electrical self-control system.

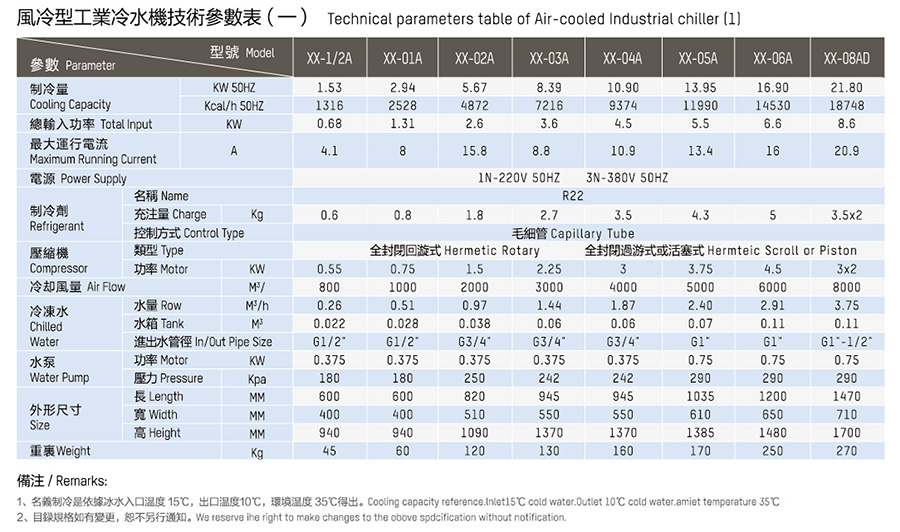

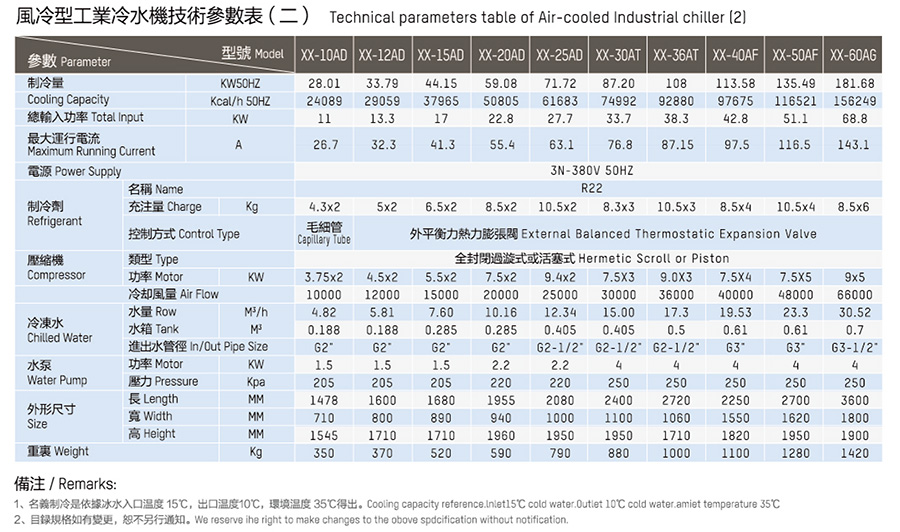

Technical parameter table of chiller: