Product Description

The exclusive screw rotor profile design of the air-cooled screw chiller unit is driven directly by the motor, with outstanding compression efficiency and quiet operation. The advanced economizer and dual circuit design, slide valve stepless adjustment of compressor capacity, and precise dynamic control of electronic expansion valve optimize the system's partial load efficiency with intelligent energy-saving reset function. Through high-sensitivity temperature sensors, the chilled water is automatically adjusted when the return water or outdoor environment temperature drops. The outlet temperature has a unique air conditioning and ice making automatic switching function, achieving efficient integration with the ice storage system and perfectly meeting the comfort requirements of energy-saving buildings. The lowest outlet temperature of the evaporator can reach -12 ℃, and the highest outlet temperature of the condenser can reach 63 ℃

Superior performance

The host adopts an internationally advanced semi closed screw compressor, motor, and compressor integration, without any concern for shaft seal leakage;

The compressor adopts download voltage reduction starting to avoid impact on the power grid;

One machine for multiple purposes, efficient heat recovery

Easy installation

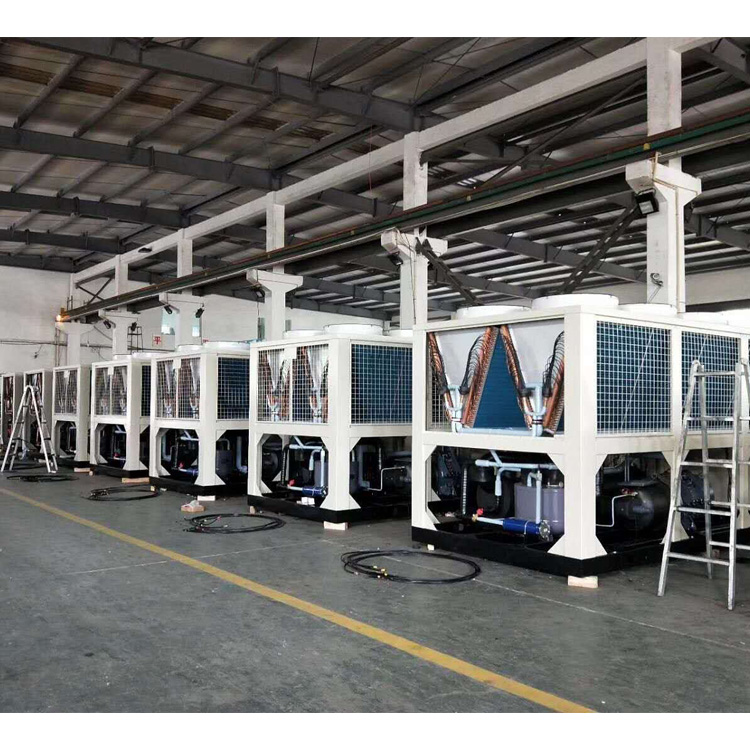

The unit mechanism is tightly arranged, occupying a small area and saving space in the computer room;

When the whole machine leaves the factory, it has been strictly debugged and turned, and has fully reached the on-site use state;

The unit has minimal vibration, and the foundation does not require seismic isolation measures, making installation simple;

During installation, simply connect the water pipes on the chilled water side of the evaporator and the cooling water side of the condenser;

Each module unit can be installed in series and parallel, or independently installed and used, suitable for different places, with a wide range of applications and strong spatial expansion and contraction;

Low operation and maintenance costs

A set of microcomputers centrally controls the operation of each module, adjusts the start stop and uniform installation of corresponding modules according to changes in system energy, effectively saving energy. At the same time, if a certain operating module in the unit fails, the microcomputer controller will automatically activate other modules to meet the requirements;

The total number of components in screw compressors is only 1/10 of that of reciprocating compressors, with a simple structure, few vulnerable parts, no inlet and outlet valves, insensitivity to temperature stroke, and extremely low failure rate;

Screw compressor can run for up to 40000 hours without any faults

Fully equipped with security protection functions

Pressure protection: high voltage protection and low voltage electrical automatic protection devices;

Motor protection: undervoltage protection, phase loss protection, reverse phase protection, overload protection, motor overheating protection, oil shortage protection;

Anti freezing protection: When the temperature of the chilled water is too low, the unit will automatically shut down;

Safety valve protection: When the refrigerant pressure exceeds a certain value, the safety exhaust valve will automatically open.

The various protections of the above equipment enable the unit to operate safely and stably.

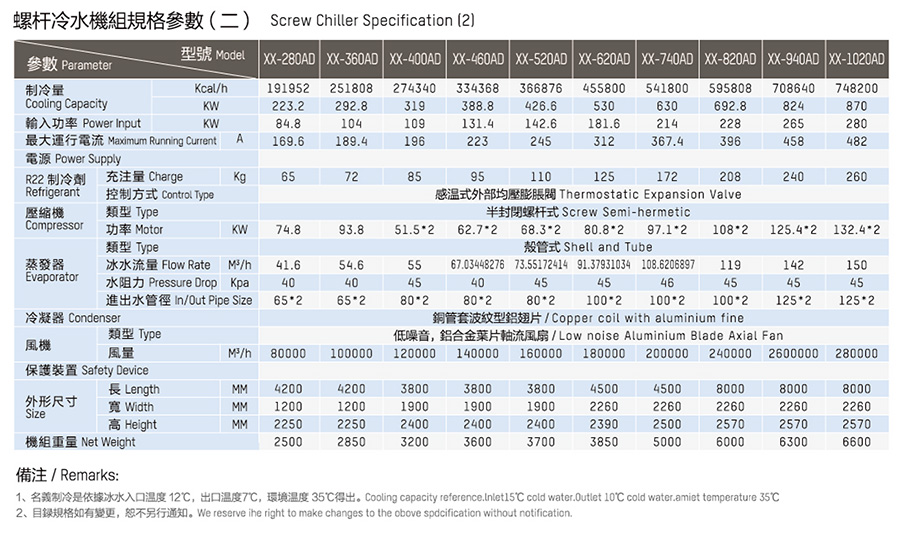

Specification parameters