Product Description

Low temperature screw machine screw chiller is also a type of chiller. Due to the use of screw compressor as its main component, it can be called low-temperature screw machine screw chiller. Its chilled water temperature range is 3 ℃~20 ℃, which can be widely used in various industrial refrigeration processes such as plastic, electroplating, electronics, chemical, pharmaceutical, printing, food processing, etc. that require chilled water, or in various central air conditioning projects such as large shopping malls, hotels, factories, hospitals, etc. that require centralized cooling with chilled water.

Product features:

(1) The compressor of the unit adopts a well-known semi enclosed screw compressor and electronic control components, equipped with a condenser and evaporator made of high-efficiency and high-quality copper tubes for heat exchange;

(2) Equipped with various safety protection devices, stable performance, low noise, long service life, and simple operation; Adopting a liquid crystal display human-machine interface, the operation is simple and convenient, and the operating status is clear at a glance;

(3) The model adopts a single compressor or a combination of multiple compressors for refrigeration system. The compressor can automatically alternate operation according to load changes, balancing the operating hours of each compressor, achieving the effect of saving energy consumption and extending the service life of the chiller unit. Easy to regulate energy and more energy-efficient at partial loads;

(4) Open structure, beautiful appearance of the whole machine, simple structure, can check the operation of the unit at any time, easy to install and maintain;

Working principle

When the unit is cooling, the compressor sucks the low-temperature and low-pressure refrigerant from the evaporator into the cylinder. After the compressor works, the refrigerant vapor is compressed into high-temperature and high-pressure gas, which enters the condenser through the exhaust pipe. The high-temperature and high-pressure refrigerant gas exchanges heat with the cooling water in the condenser, transferring heat to the cooling water and taking it away, while the refrigerant gas condenses into high-pressure liquid. The high-pressure liquid coming out of the condenser is throttled and depressurized by the thermal expansion valve before entering the evaporator. In the evaporator, the low-pressure liquid refrigerant absorbs the heat of the chilled water and vaporizes, causing the chilled water to cool down and become the required low-temperature water. The vaporized refrigerant gas is sucked back into the compressor for compression and discharged into the condenser, repeating this cycle to achieve cooling of the chilled water.

The chilled water coming out of the unit enters the end devices such as fan coil units and variable air volume air conditioning units indoors, where it exchanges heat with convective air. During this process, the water absorbs heat from the indoor air (dissipating heat to the indoor air), causing the temperature to rise. The indoor air, after passing through the indoor heat exchanger, decreases in temperature and is driven by the fan to enter the room, thereby reducing the indoor air temperature. The chilled water, which has risen in temperature, enters the unit again under the action of the water pump and circulates in this way to achieve continuous cooling

The company adheres to the business philosophy of "developing with integrity, surviving with quality, and creating benefits with brand", and takes "first-class brand, first-class quality, and first-class service" as its corporate purpose. It sincerely treats every customer and is loyal to establishing long-term cooperative relationships with new and old friends at home and abroad.

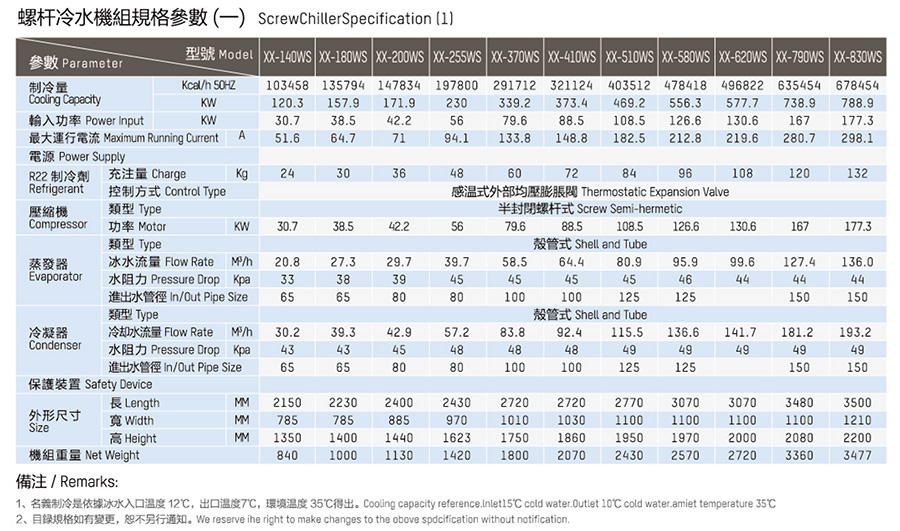

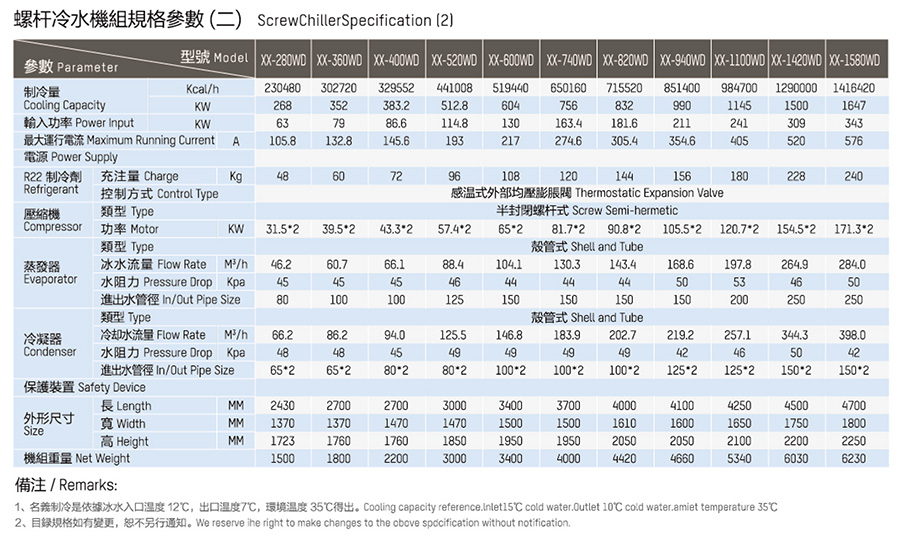

Specification parameters