Features of Zinc Alloy Die Casting Mold Temperature Machine

1. Return oil temperature display function

2. Automatic exhaust function upon startup

3. Heating power switching function

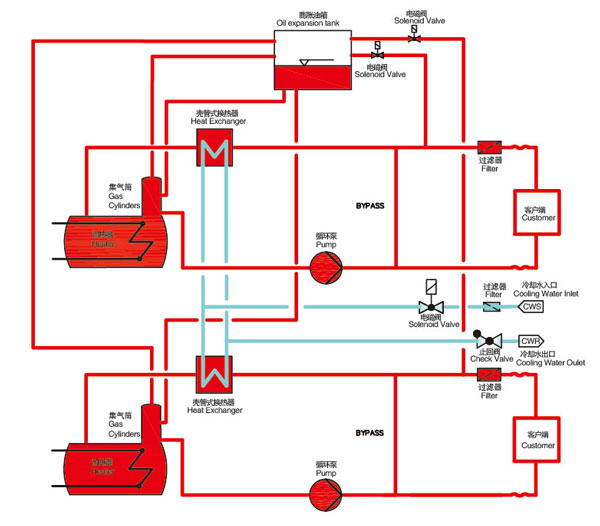

4. Hot oil BY-PASS pressure relief circuit

5. Multi point temperature control unit can be customized

6. Oil pump horsepower and heating power can be customized

7. Temperature control accuracy: PID ± 1 ° C

8. Isolated electrical control box Extend the service life of electrical appliances

9. The electrical appliance adopts OMRON. FUJI TE. LG. MOELLER. ABB. WEST.

10. Temperature control range: Inlet oil temperature+15 ℃ → 350 ℃

11. SUS304 stainless steel or carbon steel integrated pipeline, reducing pipe resistance and rust scale

12. The temperature control table adopts OMRON or WEST microcomputer dual group P I. D control, trigger type internal storage automatic calculation, accurate and reliable, saving more than 35% electricity

13. Complete safety protection, fault display, and maintenance Maintenance does not require professional personnel. Machine specifications

14. Explosion proof device (optional)

15. Blow back oil function (optional)

16. Instant cooling shutdown function (optional)

17. RS485 communication function enables automated management (Purchase)

18. Control method: Imported microcomputer or PLC control (optional)

Zinc alloy die-casting mold temperature machine protection device

Oil circulation temperature controller/oil temperature machine safety protection and indication system:

1. Power supply under phase and phase sequence protection

2. Total leakage protection switch

3. Pump reverse protection

4. Pump overload protection

5. High temperature protection

6. Pipeline blockage in BY-PASS pressure relief circuit

7. Temperature anomaly protection

8. Abnormal alarm buzzer

9. Lack of media protection

10. Contactor jamming protection

11. Pressure detection (stop heating due to abnormal pressure)

Schematic diagram of zinc alloy die-casting mold temperature machine

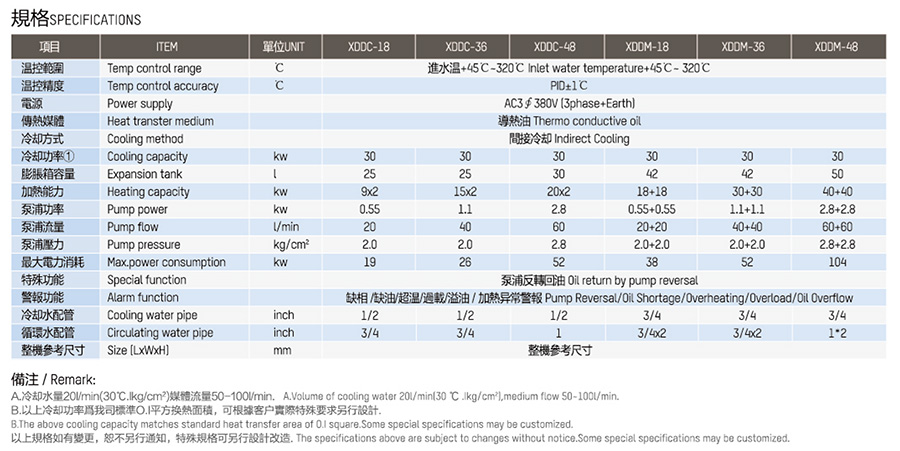

Specification parameters of zinc alloy die-casting mold temperature machine